Calculation of melting point of Al-Mg Alloy using Neural Network Force Field#

Neural Network Potential (NNP) reproduce the environment around atoms, so it can be applied to random alloy systems if there are sufficient training data and cell volume. We made training data with different fractions via Self-Learning Hybrid Monte Carlo (SLHMC) method, and made NNP which can be applied to alloy systems.

Creation of training data via SLHMC method#

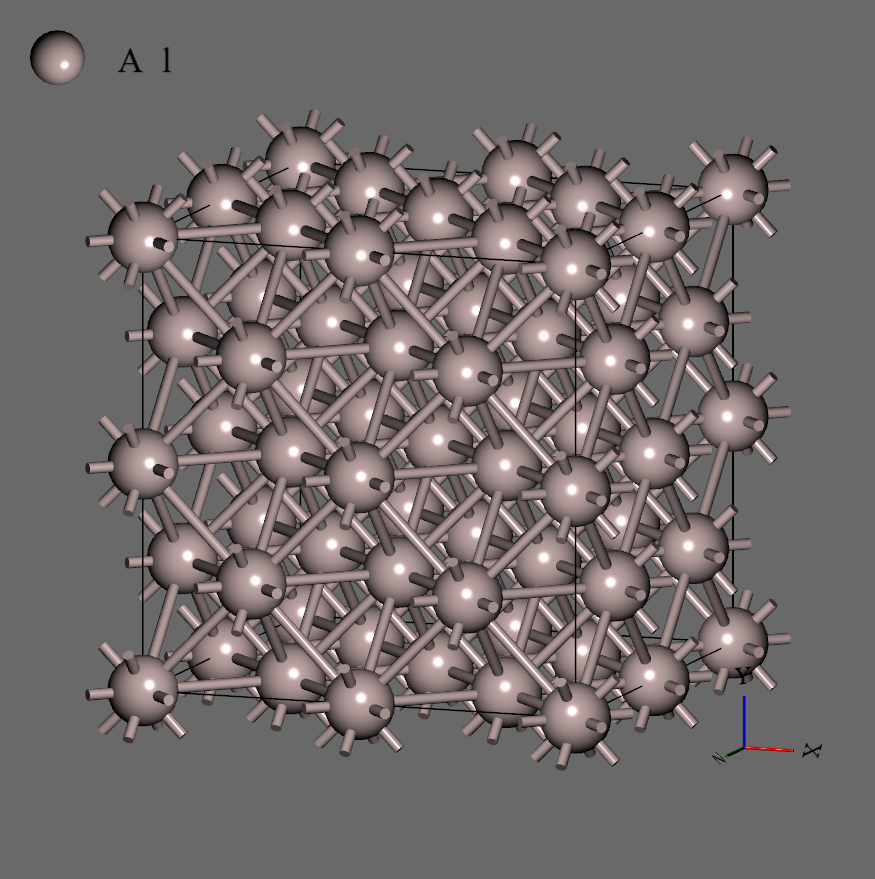

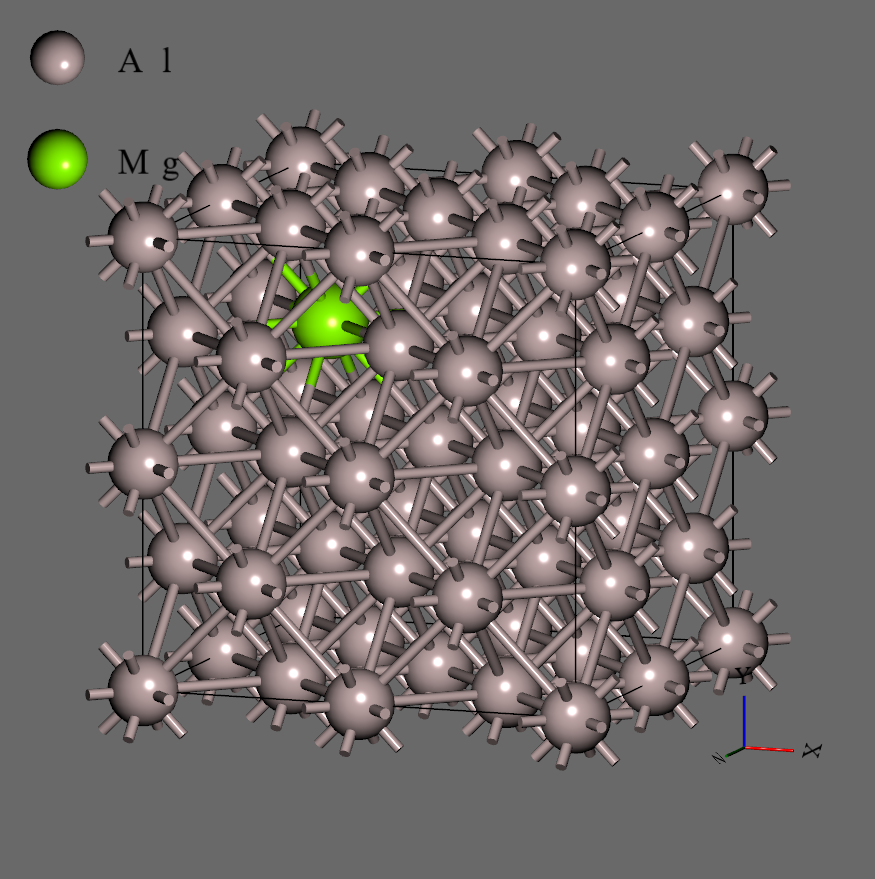

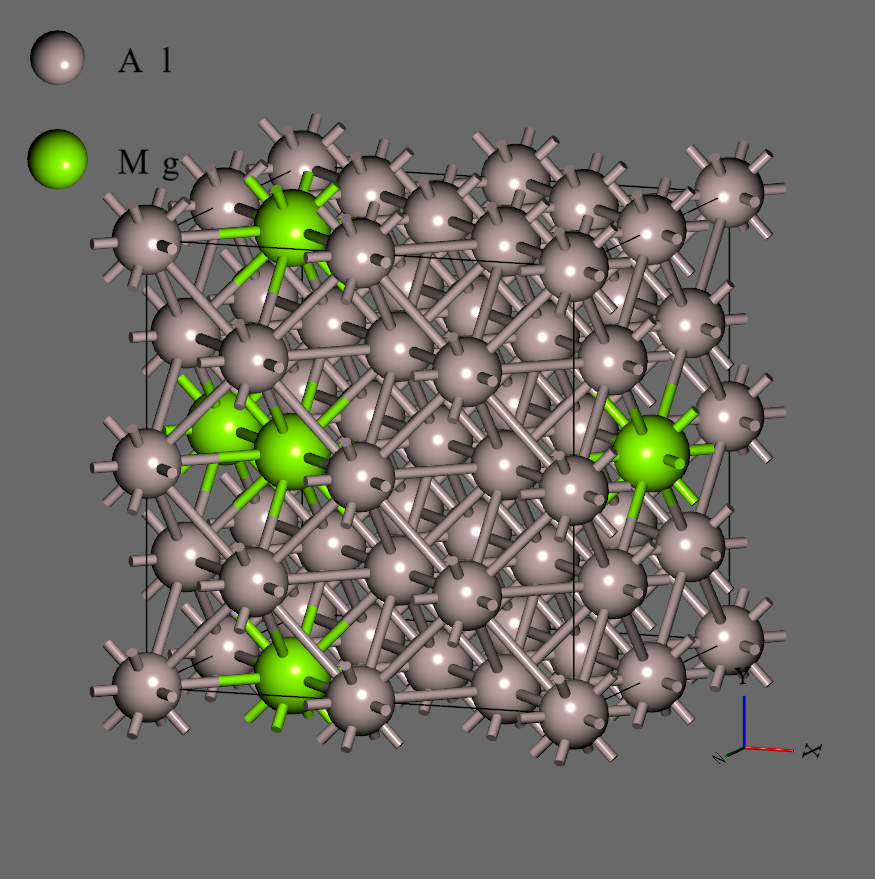

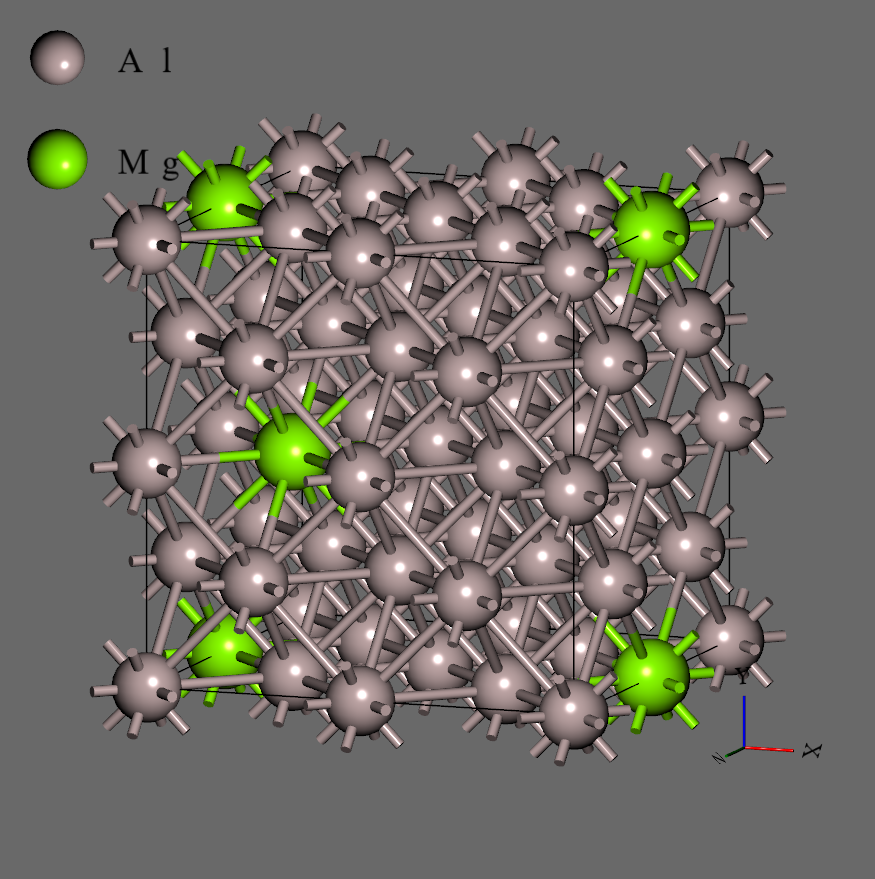

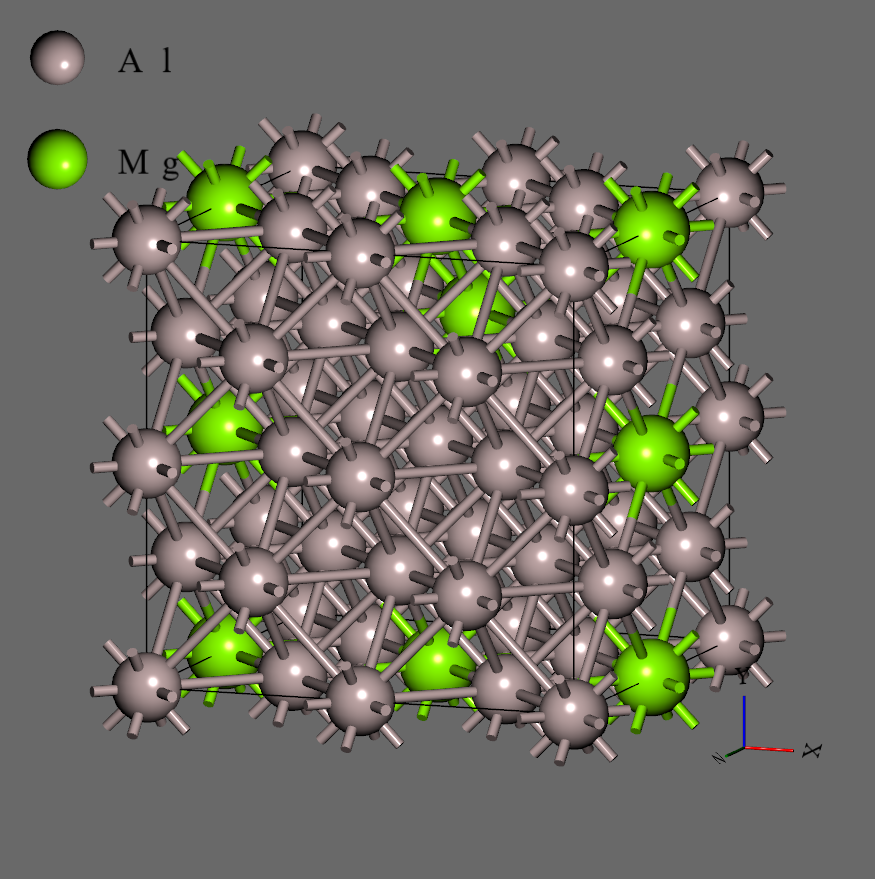

- For the initial structure, the 32 atoms system which duplicate fcc Al crystal that taken from Materials Project (mp-134) to x, y and z directions was used. In addition, the structures that 1 – 4 atoms of them were replaced to Mg were used as the initial structures too.

- Molecular Dynamics (MD) Calculation performed with NPT ensemble. First-principle MD to create initial force field was done 200 steps, and then NNP-MD was done 10 – 320 steps (2.5 – 80 fs) per one SCF calculation. To reproduce the molten state, the temperature was settled at 2000 K, and the degree of freedom of cell deformation was settled to Triclinic.

- The Density Functional Theory (DFT) using pseudo potentials was used for SCF calculations. GGA-PBE functional was used as exchange-correlation functional. The cut-off energy was 40.0 Ry, and k-point was Γ-point only. The spin polarization was not considered.

- The structure of Neural Network was 40-nodes x 2-layers, and twisted tanh function was used as an activation function. 80 Chebyshev functions were used as symmetric functions, and the cut-off radius was settled at 6 Å.

Mg 3 atoms

Mg 4 atoms

Using Intel Xeon Gold 6330 (2 CPUs, 56 cores), the creation of training data finished in about 15 h per structure. At the final, the number of training data including the accepted and the rejected was 5200 per one structure, 26000 total.

NNP creation#

- A new NNP was trained using training data created in previous section.

- The structure of neural network was 50-nodes x 2-layers, and twisted tanh function was used as an activation function. 100 Chebyshev functions were used as symmetric functions, and the cut-off radius was settled 6.5 Å.

- During the training, 10% of the training data were split as test data, and in-situ test was done per one epoch.

Using the same CPUs/cores as which used when the training data created, training finished 10000 epochs in about 15 h.

Calculation of melting point of alloy system#

- Using the created NNP, the NNP-MD calculation was done for the system imitates Al alloy, and measured the melting points of them.

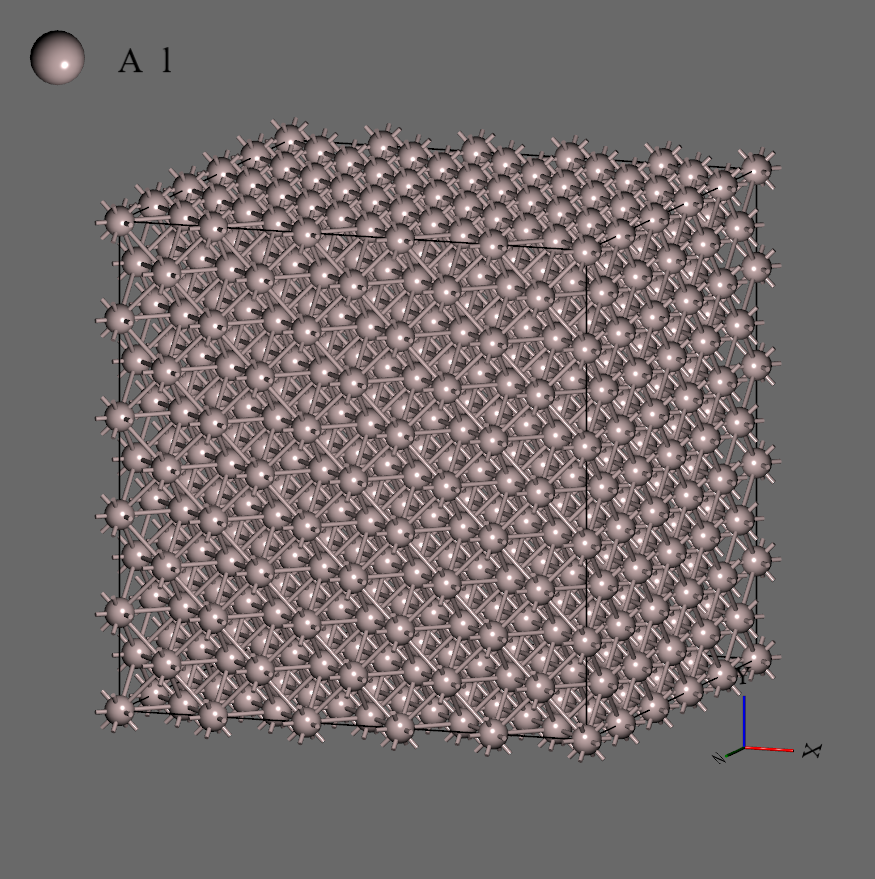

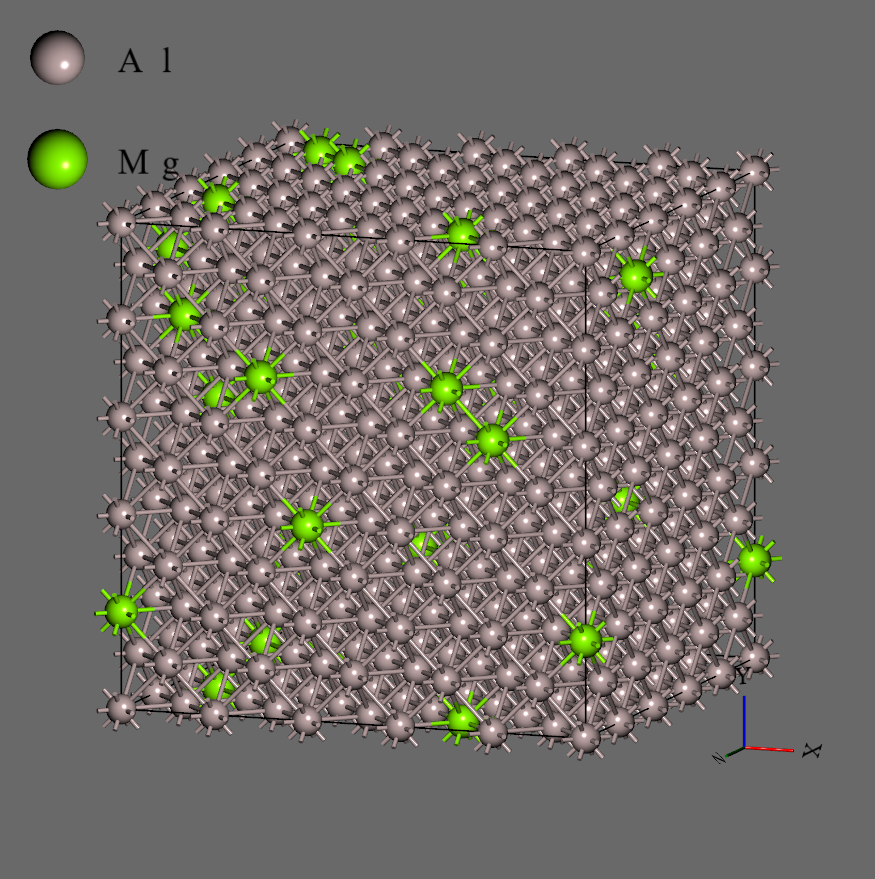

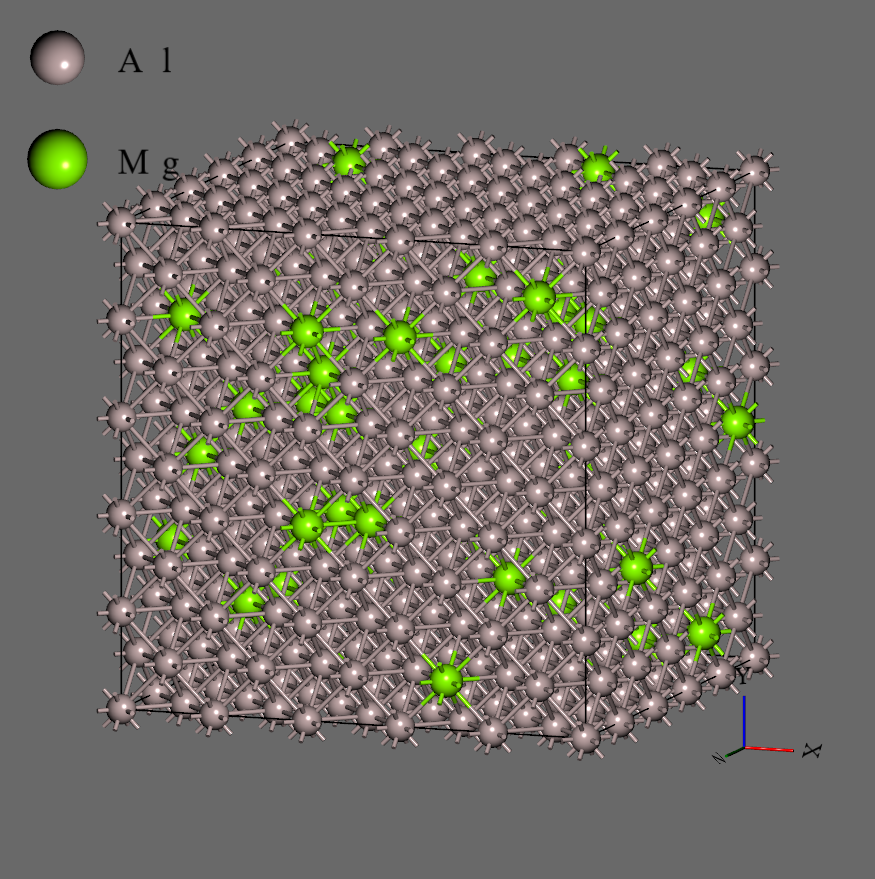

- For the structure, the 500 atoms system which the fcc Al crystal structure which is same as used in training data creation (mp-134) was duplicated 5-time each of x, y and z directions was used.

In addition, the structures which the 5% and 10% of them were replaced to Mg were used. The training data include 3.1%, 6.3%, 9.4%, 12.5% Mg fractions, so 5% and 10% Mg fractions were included to training range, but not included directly in the training data. - The MD calculation performed with NPT ensemble. The pressure was 1 bar. The temperature started at 1 K, and raised to 2000 K in 250 ps.

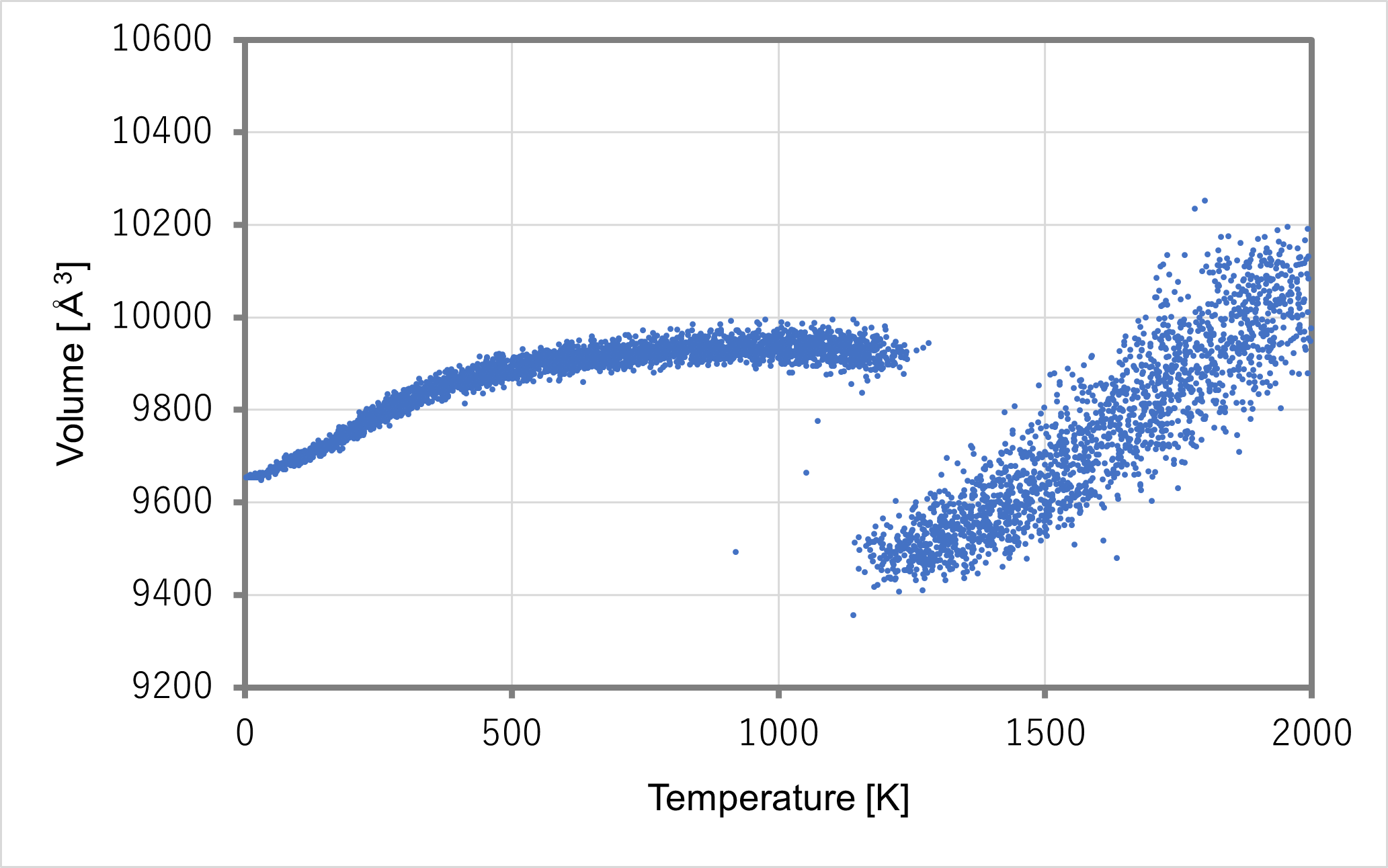

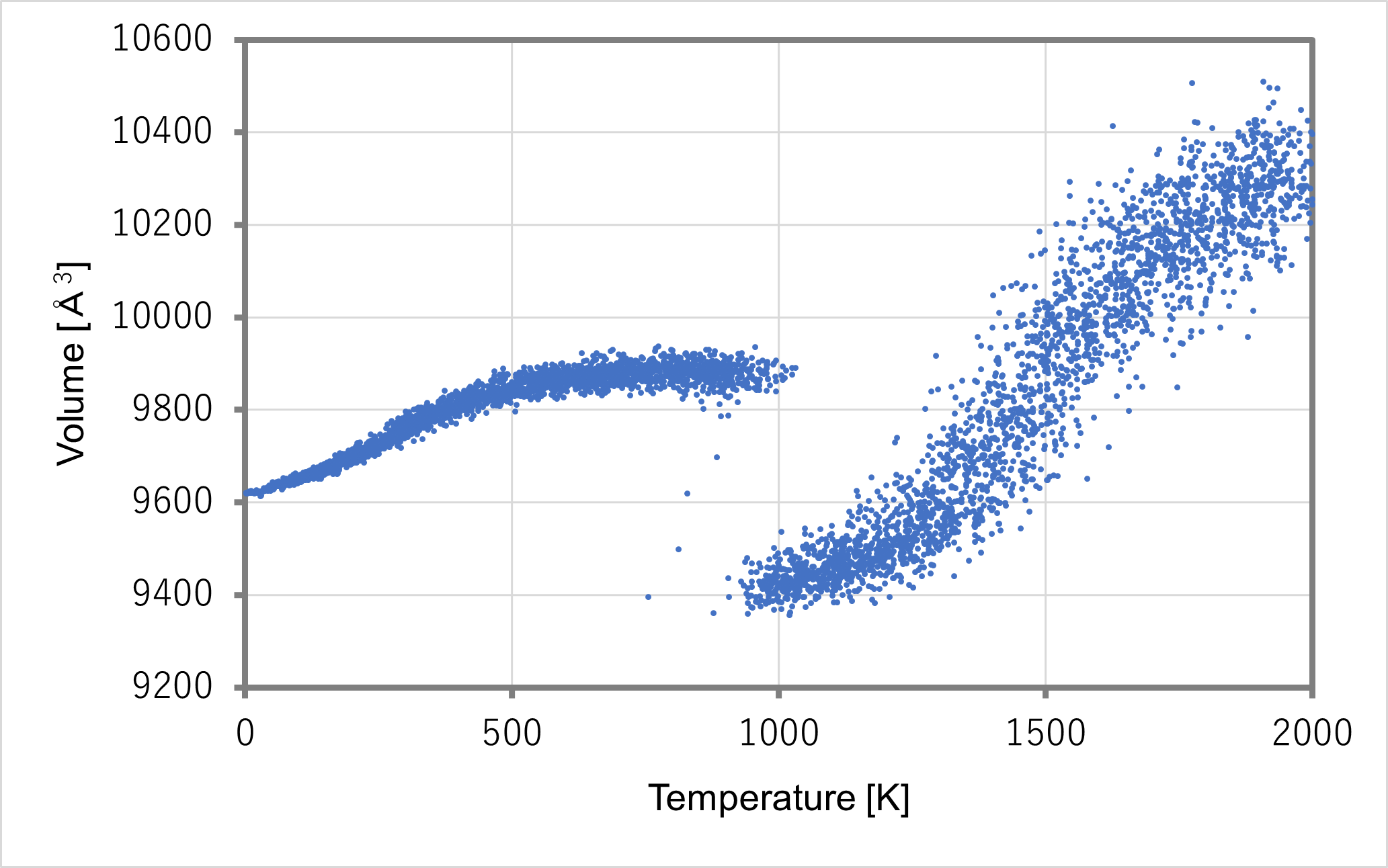

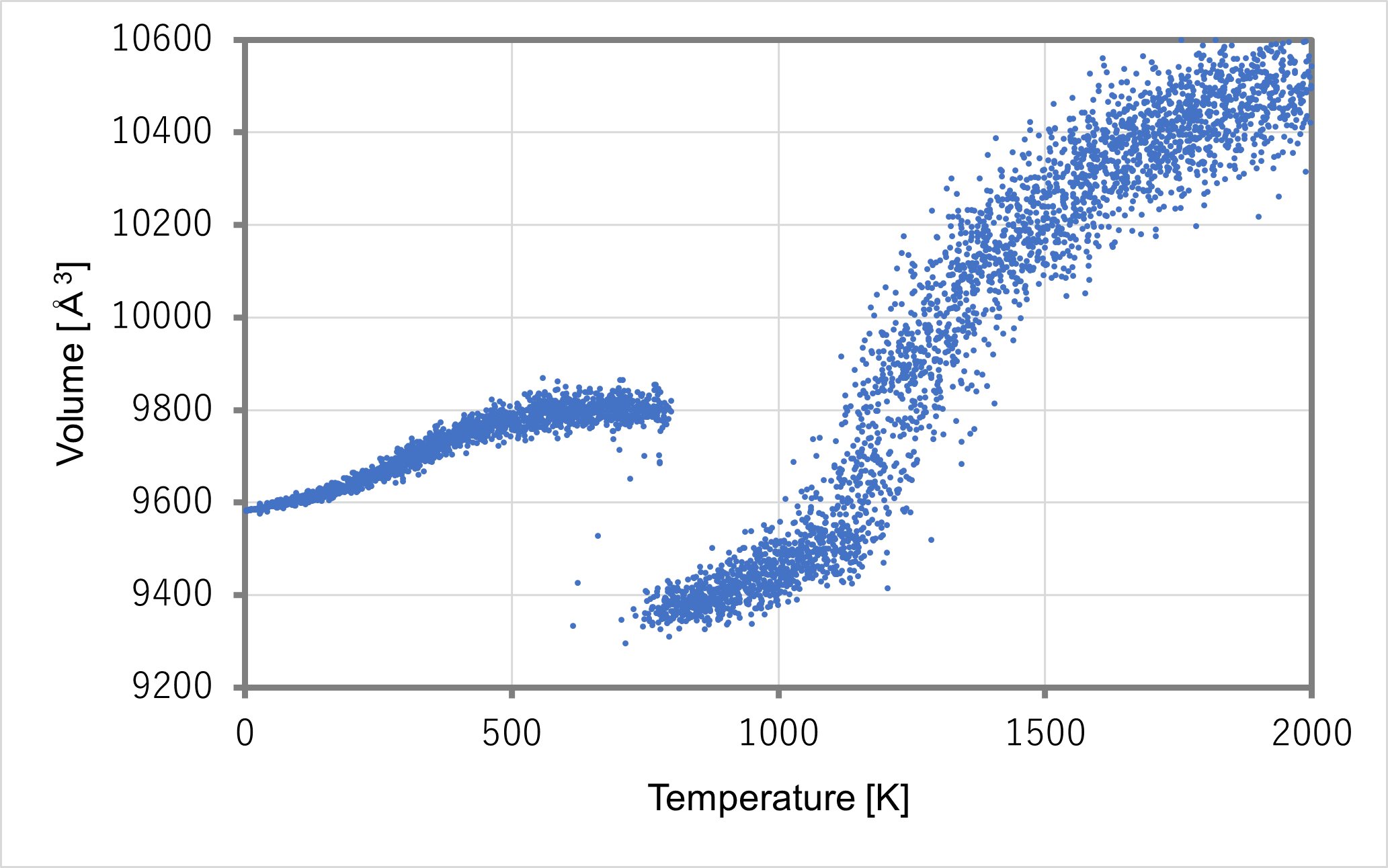

The below graph shows the volume change versus the temperature which obtained as a result of MD calculation.

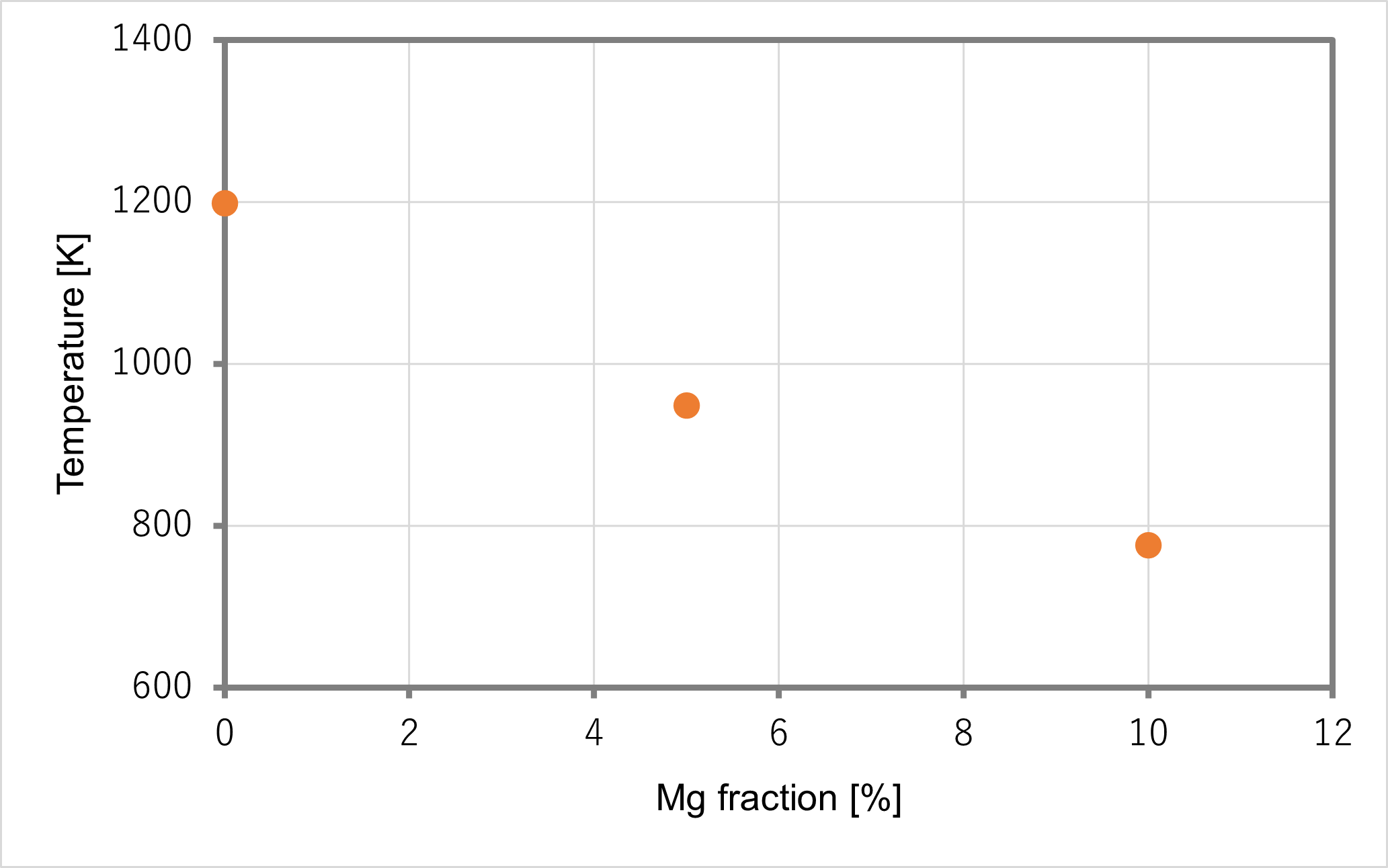

Along with the raising of Mg fraction, the temperature at which volume change occurs changed as 1198.2 K, 948.2 K and 775.4 K. According to Al-Mg phase diagram1, the melting points of them are 660 °C, 633 °C and 606 °C, so the magnitude relation of melting points can be reproduced using NNP-MD.

Melting-point change vs. Mg fraction

Al + Mg 10%

関連ページ#

- ニューラルネットワーク分子動力学システム Advance/NeuralMD

- 解析分野:ナノ・バイオ

- 産業分野:材料・化学

- Advance/NeuralMD Product Information

- Advance/NeuralMD Documentation

-

M.Mezbahul-Islam et al., Journal of Materials, Vol.2014, 2014, 704283 ↩